Call: 08071932050

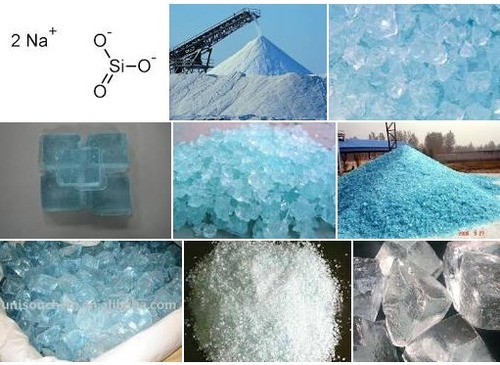

Sodium Silicate Powder

MOQ : 1 Kilograms

Sodium Silicate Powder Specification

- Application

- Detergents, adhesives, water treatment, cement, ceramics, paper, textiles

- HS Code

- 28391900

- Storage

- Store in a cool, dry place in tightly closed containers

- Properties

- Alkaline, soluble in water, hygroscopic, adhesive, binder and deflocculant properties

- Poisonous

- Non-poisonous, but caustic

- Smell

- Odorless

- Purity

- 99%

- Shelf Life

- 24 months

- Product Type

- Inorganic Compound

- Refractive Rate

- 1.520 (for aqueous solution)

- Molecular Formula

- Na2SiO3

- Molecular Weight

- 122.06 g/mol

- Structural Formula

- Na2OnSiO2

- Appearance

- White or off-white powder

- Taste

- Alkaline

- Shape

- Granular or fine powder

- EINECS No

- 215-687-4

- Solubility

- Soluble in water

- Ph Level

- Highly alkaline (pH 11-13, 1% solution)

- Melting Point

- 1088C

- Ingredients

- Sodium oxide and silicon dioxide

- Usage

- Used as a binding agent, deflocculant, corrosion inhibitor, and in fireproofing

- Grade

- Industrial

- CAS No

- 1344-09-8

- Density

- 2.4 Gram per cubic centimeter(g/cm3)

- Physical Form

- Powder

- Toxicity

- Non-toxic but can cause irritation

- Manufacturing Method

- Fusion of sodium carbonate and silica sand

- Main Hazard

- Irritant to skin and eyes

- Packing Type

- Bags, HDPE drums, jumbo bags

- Environmental Impact

- Low; biodegradable

- Moisture Content

- 2.0%

- Color

- White to off-white

- Na2O : SiO2 Ratio

- Varies from 1:2 to 1:3.5 depending on application

- Iron content

- <0.05%

- pH (1% solution)

- 11.5 - 13.0

- Particle Size

- < 150 microns

- Free Alkali

- <0.5%

- Compatibility

- Compatible with most inorganic and some organic compounds

- Bulk Density

- 0.6 - 1.0 g/cm

Sodium Silicate Powder Trade Information

- Minimum Order Quantity

- 1 Kilograms

- Supply Ability

- 15000 Kilograms Per Month

- Delivery Time

- 02 Days

About Sodium Silicate Powder

we are the manufacturer of sodium silicate, Sodium Silicate is a compound mixture of sodium oxide i.e. Na2O with silica sand i.e. SiO2 with water. Sodium silicate is also called water glass. There are two process to manufacture liquid Sodium Silicate.

Other Details:

- Formula: Na2SiO3

- IUPAC ID: Sodium metasilicate

- LD50 (median dose): 1153 (rat, oral)

- Gibbs free energy (fG): 1427 kJ/mol

- Abbreviations: E550

- Other cations: Potassium silicate

Versatile Industrial Applications

Sodium Silicate Powder serves numerous industries due to its adhesive, binding, and corrosion-inhibiting properties. It plays a vital role in detergent formulation, water treatment processes, cement manufacturing, ceramics production, and as a deflocculant in paper and textile industries. Its high solubility, alkaline profile, and adjustable Na2O : SiO2 ratio ensure compatibility and efficacy across a multitude of uses.

Safety and Environmental Features

While sodium silicate powder is non-toxic, it is an irritant to the skin and eyes due to its caustic and highly alkaline nature. Users should follow standard safety protocols, such as wearing gloves and eye protection during handling. Its low iron content and biodegradable properties contribute to minimal environmental impact, making it a sustainable choice for industrial applications.

Quality Assurance and Storage Recommendations

Produced via the fusion of sodium carbonate and silica sand, sodium silicate powder is supplied in tightly sealed bags, HDPE drums, or jumbo bags to maintain its low moisture content (2.0%) and purity. Proper storage in cool, dry places extends its shelf life to 24 months, ensuring reliable batch performance and maintaining its optimal adhesive and binding capabilities.

FAQs of Sodium Silicate Powder:

Q: How is sodium silicate powder manufactured?

A: Sodium silicate powder is produced through the fusion process, which involves heating sodium carbonate and silica sand at high temperatures, resulting in a highly pure and homogenous powder with excellent alkaline properties.Q: What are the main uses of sodium silicate powder in industry?

A: Industrially, sodium silicate powder is utilized in detergents, adhesives, water treatment, cement, ceramics, paper, and textiles. It functions as a binder, deflocculant, corrosion inhibitor, and fireproofing agent due to its adhesive and alkaline attributes.Q: When should I use sodium silicate powder as a deflocculant?

A: Sodium silicate powder is ideal as a deflocculant when improving dispersion and reducing viscosity in ceramic slurries, industrial wastewater treatment, and paper pulp processing, optimizing flow and workability.Q: Where can sodium silicate powder be safely stored to maintain its quality?

A: Sodium silicate powder should be stored in a cool, dry place in tightly closed containers such as bags, HDPE drums, or jumbo bags to prevent moisture absorption and maintain a shelf life of up to 24 months.Q: What safety measures are recommended when handling sodium silicate powder?

A: Since sodium silicate powder is an irritant, users should wear gloves, protective eyewear, and avoid direct skin and eye contact. Adequate ventilation and following industrial safety guidelines are essential during use.Q: What are the benefits of using sodium silicate powder in water treatment and cement production?

A: In water treatment, sodium silicate powder acts as a corrosion inhibitor and water softener, while in cement production, it enhances setting properties, bonding strength, and provides stability by regulating the silicate ratio.Q: Is sodium silicate powder environmentally friendly and chemically compatible?

A: Yes, sodium silicate powder is biodegradable, exhibits low environmental impact, and is compatible with most inorganic as well as selected organic compounds, supporting a broad spectrum of industrial applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Sodium Silicate Glass Category

Sodium Silicate Glass

Price Range 8.00 - 15.00 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Solubility : Soluble in water

Application : Other , Water treatment, adhesives, detergents, ceramic production, foundry, textile, pulp and paper

HS Code : 28399090

Ph Level : 11.5 (aqueous solution)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry