Sodium Silicate Glass

Sodium Silicate Glass Specification

- HS Code

- 28399090

- Usage

- Used in manufacturing, as binder, corrosion inhibitor, and flame retardant

- Product Type

- Inorganic Chemical Compound

- Taste

- Alkaline, caustic

- Poisonous

- Yes, toxic and caustic

- Molecular Weight

- 122.06 g/mol

- Physical Form

- Solid

- Purity

- 98%

- Application

- Water treatment, adhesives, detergents, ceramic production, foundry, textile, pulp and paper

- Grade

- Industrial Grade

- Melting Point

- Approx. 1088C

- Properties

- High alkalinity, soluble in water, forms viscous solutions, effective binder

- Solubility

- Soluble in water

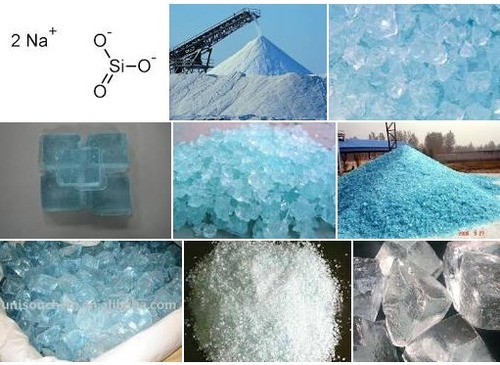

- Appearance

- Transparent, glassy

- Refractive Rate

- 1.5

- Smell

- Odorless

- Shelf Life

- 2 years

- Density

- 2.4 Gram per cubic centimeter(g/cm3)

- Ph Level

- 11.5 (aqueous solution)

- Shape

- Lumps or blocks

- Stability

- Stable under recommended storage conditions

- Compatibility

- Incompatible with acids; reacts violently

- Particle Size (if crushed)

- 230 mm

- Handling Precautions

- Use protective clothing, gloves, and eye/face protection

- Viscosity (solution)

- Depends on concentration; high viscosity at higher silicate ratio

- Packaging Size

- 25 kg, 50 kg bags or bulk

- Transport Regulations

- UN 3253, Class 8 (Corrosive)

- Temperature Range for Storage

- 535C

- Hazard Statement

- Causes severe skin burns and eye damage

- Crystal System

- Amorphous

- Color

- Colorless to slight green

Sodium Silicate Glass Trade Information

- Minimum Order Quantity

- 1 Kilograms

- Supply Ability

- 15000 Kilograms Per Month

- Delivery Time

- 02 Days

About Sodium Silicate Glass

Backed by the sound infrastructural facility and highly skilled staff, our company has been able to emerge as one of the renowned manufacturers and suppliers of Sodium Silicate Glasses. Water white in color; these silicate glasses are used in laundry, metal cleaning, as a base for detergent formulation. High binding properties, this Sodium Silicate Glasses are ideal for water proofing, dams and road construction materials. Our clients can avail these silicate glasses from us at competitive prices.

Outstanding Chemical Properties

Sodium Silicate Glass provides high alkalinity, solubility in water, and a refractive index of 1.5. Its amorphous, glassy form yields a viscous solution, especially at higher concentrations, ensuring robust performance in industrial applications. Its transparency and glassy texture make it ideal for various manufacturing processes.

Versatile Industrial Applications

Owing to its effective binding properties and corrosive inhibition, Sodium Silicate Glass is prominent in water treatment, adhesives, detergents, ceramics, foundries, textiles, pulp, and paper industries. Its functionality extends to roles as a flame retardant and in the production of a diverse range of manufactured goods.

Safe Handling & Storage Requirements

To maintain stability and efficacy, sodium silicate glass should be stored between 535C in dry conditions. Protective clothing, gloves, and eye/face shields are essential during handling due to its severe skin and eye irritation hazard. It must not be stored with acids, as violent reactions can occur.

FAQs of Sodium Silicate Glass:

Q: How should Sodium Silicate Glass be stored for maximum stability?

A: Store Sodium Silicate Glass in a dry environment, away from acids, within a temperature range of 535C. Ensure the packaging is sealed properly and avoid exposure to moisture or incompatible substances to maintain its 2-year shelf life.Q: What are the common industrial applications of Sodium Silicate Glass?

A: Sodium Silicate Glass is widely used in water treatment, adhesives, detergents, ceramics, foundry work, textile processing, and pulp and paper production. Its high alkalinity and binding properties also make it valuable as a corrosion inhibitor and flame retardant.Q: When is personal protective equipment (PPE) necessary during handling?

A: PPE is always required when handling Sodium Silicate Glass. Its caustic and toxic nature means it can cause severe skin burns and eye damage. Always wear protective clothing, gloves, and appropriate eye or face protection.Q: Where should Sodium Silicate Glass not be stored or used?

A: It must never be stored or mixed with acids, as it reacts violently with them. Store separately from acidic chemicals and prevent accidental contact to ensure safety.Q: What is the process for dissolving Sodium Silicate Glass?

A: To dissolve, gradually add Sodium Silicate Glass lumps or blocks to water with agitation. Adjust concentration based on required viscosity; higher silicate ratios increase viscosity. Always avoid using acidic water sources.Q: How does using Sodium Silicate Glass benefit manufacturing processes?

A: It provides strong binding, corrosion resistance, and enhances fire-retardant properties in products. Its high purity and reliable solubility contribute to efficient and safe production in multiple industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sodium Silicate Glass Category

Sodium Silicate Powder

Price Range 8.00 - 15.00 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

CAS No : 1344098

Refractive Rate : 1.520 (for aqueous solution)

Properties : Alkaline, soluble in water, hygroscopic, adhesive, binder and deflocculant properties

Solubility : Soluble in water

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry